Check Regularly (Air Compressor Motor lubrication Oil)

Inspection of the belt:

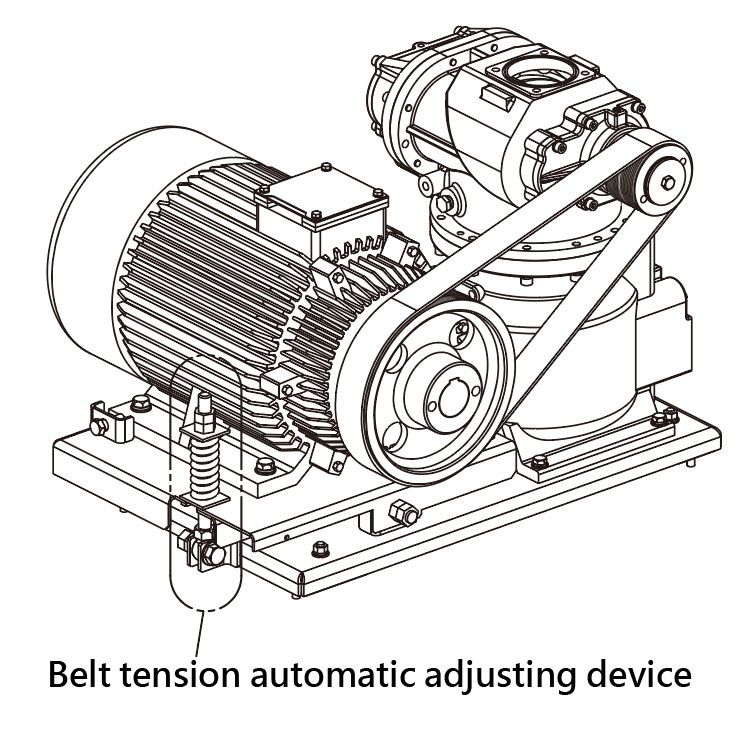

The compressor is equipped with automatically adjusting for the belt tension, which can correct the belt tension drop caused by perennial use. Please check the belt regularly.

Notice

The belt inspection must be carried out after shutdown and power cut off. It is forbidden to keep hands close to the belt during operation to avoid injury.

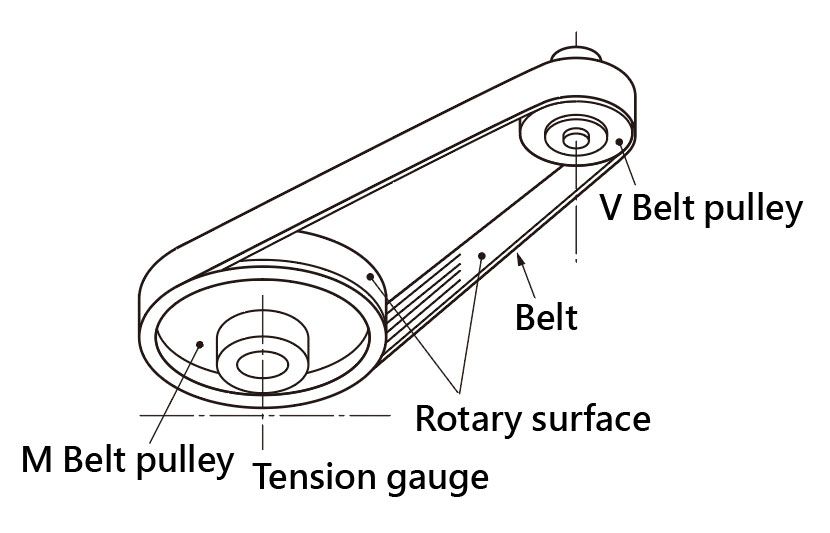

1 Visual inspection of the belt &belt pulley

- Check the belt pulley rotating surface whether there are gaps and cracks in the belt edges. In the same way, check there is any abnormal wear and tear on the wheel surfaces of V belt pulley and M belt pulley.

- Check whether there is belt slippage when the compressor starts or runs.

2 Measuring method of belt tension

Please use a special tension meter to measure the tension of the belt. Please consult the dealer or Dolomann for details.

Notice

If the tension of the belt exceeds the set time, it will not only greatly shorten the life of the belt, but also lead to various unpredictable accidents.

Specification Table

| Item | Pressure spec. | Belt width | Belt unit | Tension | |

|---|---|---|---|---|---|

| Type / Unit | MPa | m | kg/m | kgf | N |

| OSP-22M5A(R)N2 | 0.7 | 0.425 | 0.228 | 140~179 | 1373~1755 |

| OSP-22M6A(R)N2 | 0.422 | 123~157 | 1206~1540 | ||

| OSP-22M5A(R)N2 | 0.85 | 0.424 | 140~179 | 1373~1755 | |

| OSP-22M6A(R)N2 | 0.415 | 123~157 | 1206~1540 | ||

| OSP-22M5A(R)N2 | 1.0 | 0.425 | 140~179 | 1373~1755 | |

| OSP-22M6A(R)N2 | 0.430 | 123~157 | 1206~1540 | ||

| OSP-37M5A(R)N2 | 0.7 | 0.506 | 0.171 | 116~135 | 1138~1324 |

| OSP-37M6A(R)N2 | 0.51 | 101~120 | 990~1177 | ||

| OSP-37M5A(R)N2 | 0.85 | 0.498 | 116~135 | 1138~1324 | |

| OSP-37M6A(R)N2 | 0.499 | 101~120 | 990~1177 | ||

| OSP-37M5A(R)N2 | 1.0 | 0.509 | 116~135 | 1138~1324 | |

| OSP-37M6A(R)N2 | 0.504 | 101~120 | 990~1177 | ||